University of Plymouth STEAM Labs

The University of Plymouth is looking to reinforce its reputation as an innovative centre of excellence for engineering research, teaching and learning. The new Engineering and Design facility (NEDF) has been constructed on the western edge of the main Plymouth campus and provides a new home for the specialist laboratories and teaching facilities of the School of Engineering, Computing and Mathematics and the School of Art, Design and Architecture.

The Challenge

The STEAM Laboratory is a new, active learning facility, bringing experimental testing resources into one place that will enable large groups of students to learn the fundamental principles of engineering science and technology through experimentation, observation, and analysis. For first year students this will be their gateway to specialist subjects.

The STEAM Laboratory will encourage an inquiry-based pedagogy that engenders student autonomy over their learning. It is arranged across several discrete spaces occupying approximately 700 m2 in NEDF.

Upon first enquiry, we recognised that Dr Antony Robotham had a vision of how he’d like the STEAM lab to function and how it would be used by the students. With further discussion we discovered it was a passion that we at GUNT shared and the requirement aligned with our company values.

Our challenge was to meet as many of the practical requirements set out by the University as well as fulfilling the vision of creating a scaffolding to higher levels of learning. A budget was set and we ensured that the University got great value for such a large requirement.

We are proud to have collaborated with Dr Robotham and his team to help contribute to creating an Engineering centre of excellence.

The Solution

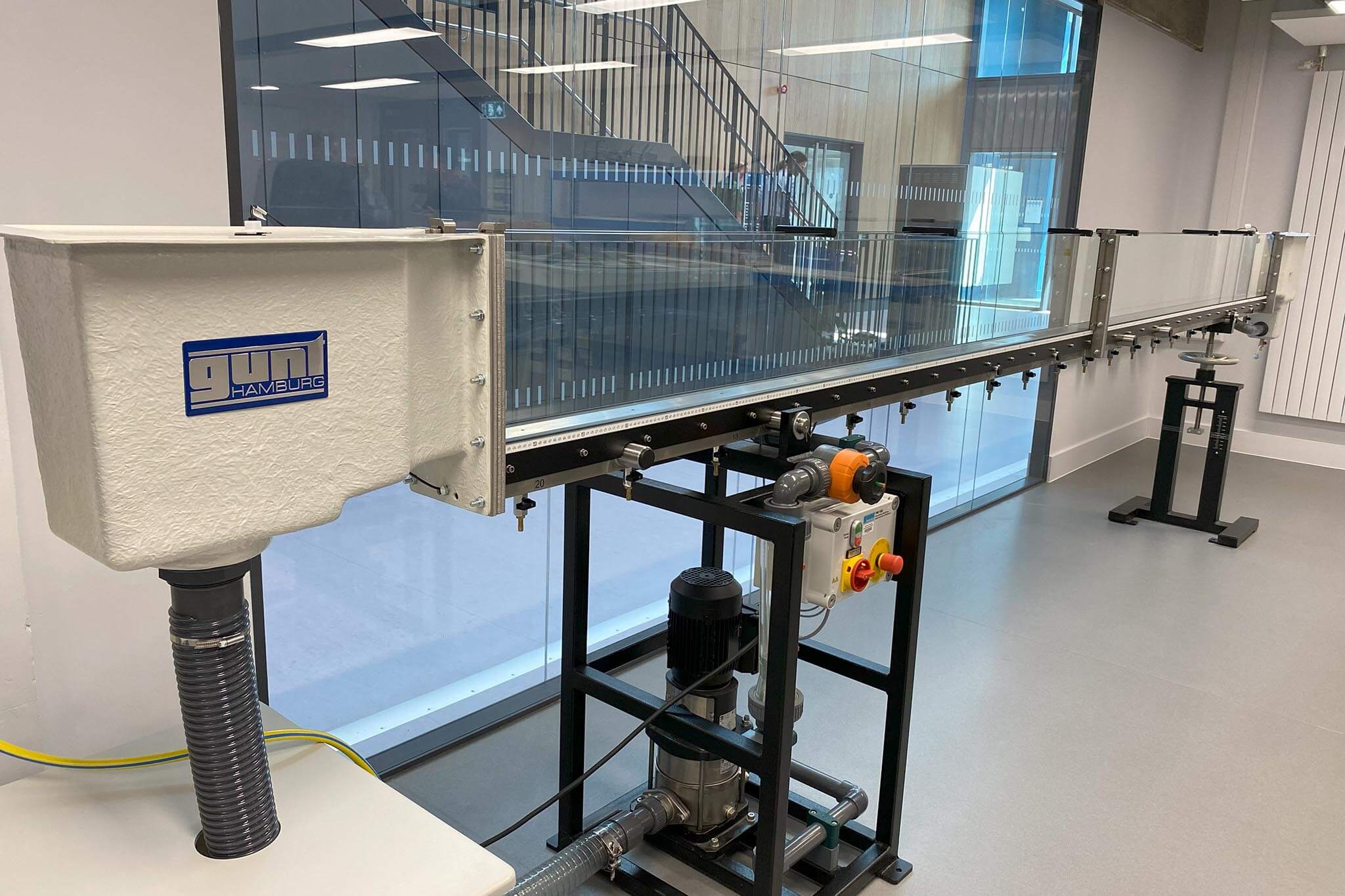

The solution proposed was to kit out brand new STEAM laboratories incorporating Fluid Mechanics, Materials Testing and Engineering Science areas. The equipment already installed at the university was old and no longer fit for purpose. We provided options for each lab section and included additional capabilities, software and student learning resources.

As with all installations, a team from our head office in Hamburg, Germany flew over to install and set up and calibrate the new equipment. Our Sales Engineer was on-site to oversee the installation.

From the beginning of this 2023/2024 project, GUNT Technology have formed a strong partnership with University of Plymouth and continue to support them in their vision going forwards.

Benefits

- Brand new equipment for a brand new lab

- Complete refurbishment of the new Engineering and Design facility (NEDF)

- Will provide a new home for the specialist laboratories and teaching facilities

- New Engineering courses to increase student intake

- Open to students and organisations

Visit the University of Plymouth news pages to see HRH Duke of Gloucester open this brand new state-of-the-art facility.

Equipment

Hydrostatics and Hydrodynamics

- FL 200 Photoelastic experiments with a transmission polariscope

- FL 200.01 Set of 5 photoelastic models

Materials Testing

- WP 140.20 System for data acquisition

- WP 400.04 Set of 10 U specimens 10×5, free cutting steel

- WP 400.05 Set of 10 R7 specimens, free cutting steel

- WP 400.06 Set of 10 R5 specimens, free cutting steel

- WP 400.07 Set of 10 R7 specimens, heat treatable steel

- WP 400.08 Set of 10 R7 specimens, construction steel

- WP 400.09 Set of 10 V specimens, construction steel

Engineering Science

Download as PDF

Download this Case Study as a PDF